Following the replacement of the control system in our reflow oven in December 2016 we encountered a problem last week where one of the glass heating elements failed and the ceramic end of the element fell apart causing the metal contact to short direct to the metal case which in turn caused the fuse to blow and the 25 amp solid state relay to destroy itself in the process.

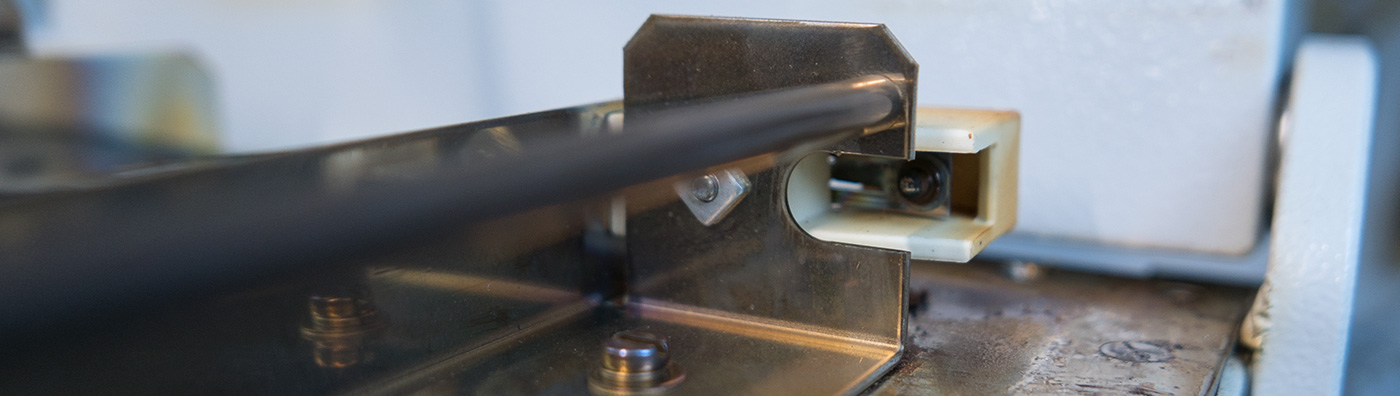

The photo above shows the original heating element holder and the metal shielding which shorted to ground when the element ceramic end failed.

I contacted the manufacturer of the reflow oven cif.fr and asked if they can supply replacement heater elements but so far (10 days) they haven’t responded to my enquiry.

As we use the reflow oven daily, we needed to fix or replace it as soon as possible and as a new reflow oven of this type costs over £3000, we decided to try to fix the current model.

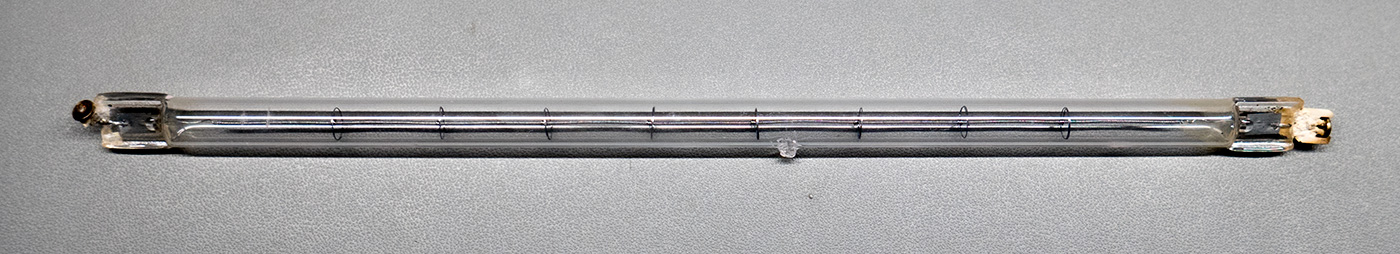

We found what appeared to be suitable replacement heating elements from RS Components in the UK and we ordered a pair of RS PRO 10mm R7s Red 254 mm 5000h Infrared (IR) Heat Lamp 230 V 1 kW (RS Stock No. 796-0136), which should have been direct replacements for the 1000w units in the oven

After running a test cook with some spare PCBs we found the intensity of the heat on the outside edges of the oven area was causing the boards to badly overheat and the middle of the oven area was not getting hot enough to reflow the solder correctly.

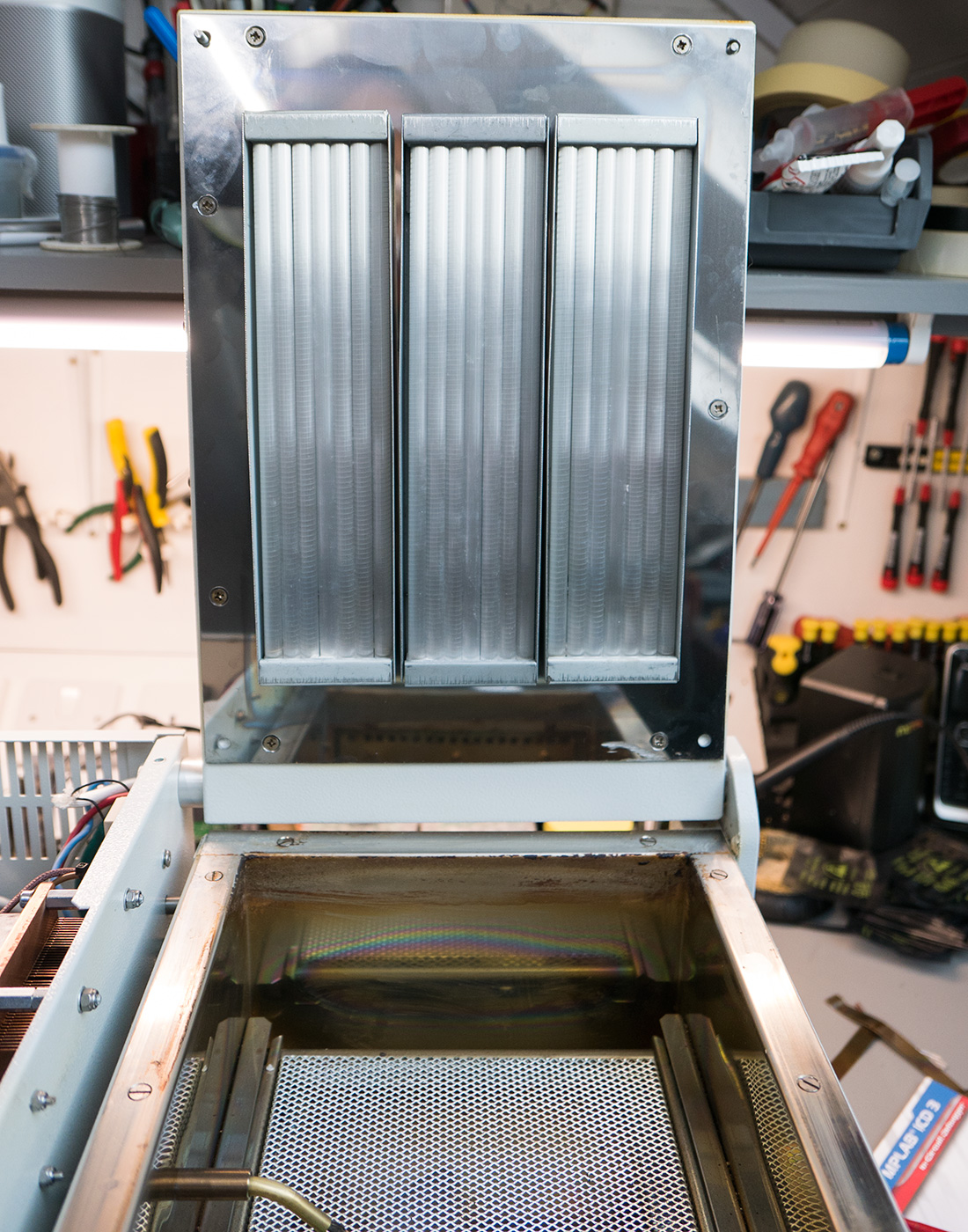

As we could not use the oven with these elements, we found an alternative which is a rectangular heating module with a Quartz Heating Element (RS Stock No. 705-4742) which measures 247 x 62.5mm.

We were able to install three of these modules into the top of the oven and this increased the heating from 2kW to 3kW. We also installed a new 50A solid-state relay to replace the broken one.

The new heating elements will give us a more even heat distribution across the full width of the oven and will improve the reflow process across the boards.

The old oven heating top plate had an opening in the middle with heat-resistant glass so you could see the oven operating, but as our reflow oven is inside a box when it is working and quartz heaters don’t give off much visible light we didn’t need this, so we made a new top plate from 2mm stainless steel which was purchased on eBay.

To ensure the new heating units would be evenly spaced we made a mock-up in Adobe Illustrator, printed this onto A4 self-adhesive paper and stuck this onto the stainless-steel sheet to ensure all the drill holes were in the correct location.

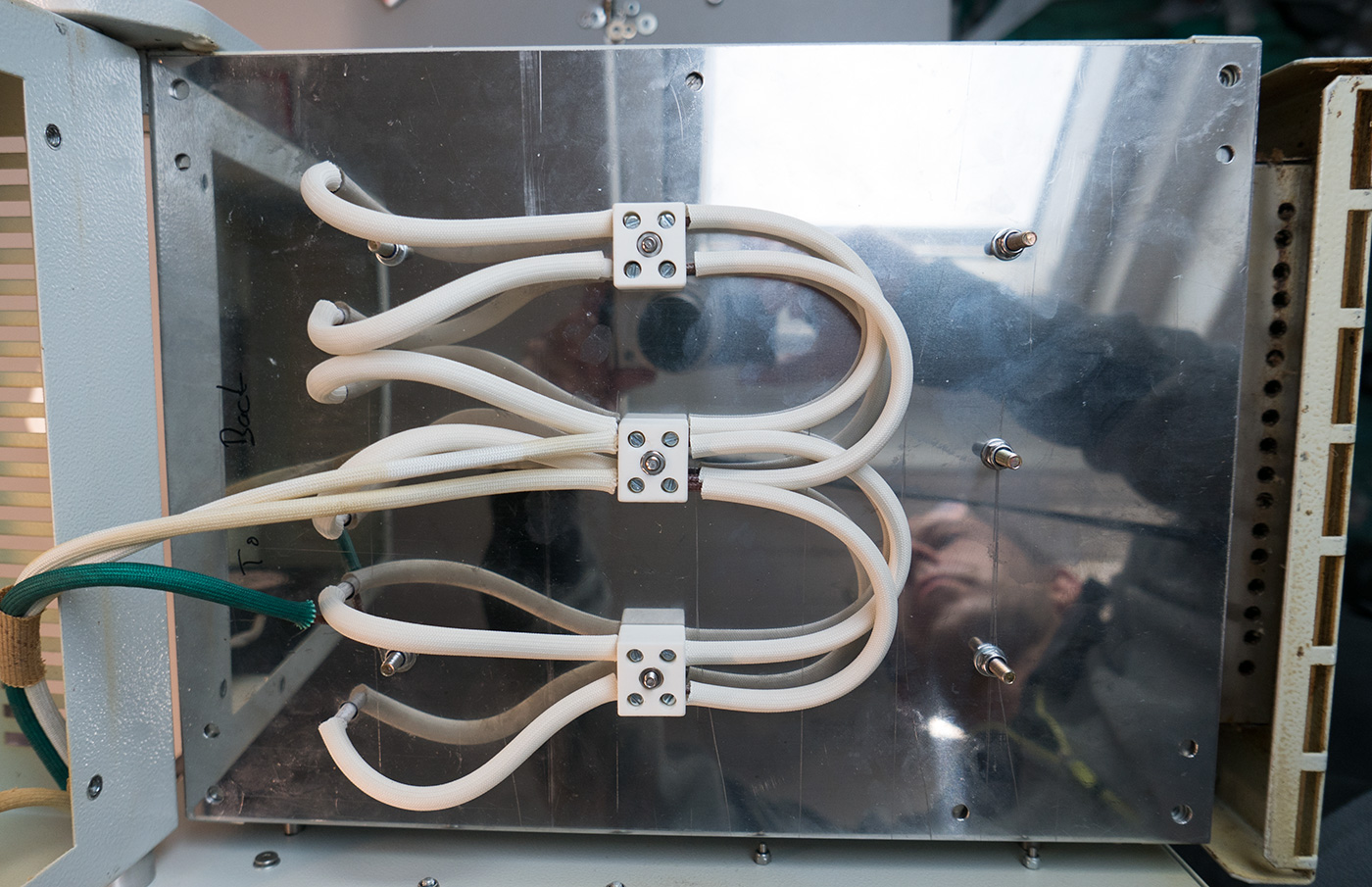

The new heating element modules were then installed, and the wires connected to ceramic terminal blocks and the cables were all covered in High-Temperature Glass Sleeving.

With all the new heating modules installed we then ran the learning mode on the Zallus Learning Controller software so it could learn the heating and cooling profile of the reflow oven.

The software profiled the heating and cooling of the new heating elements and we are now able to use the reflow oven again to build our Raspberry Pi Development Boards.

The total cost to replace the heating elements and additional hardware was less than £200. The only remaining original parts on the CIF reflow oven are now the metal case and base fan with all of the other heating components and electronics replaced or upgraded.

We tested the current consumption using our HOPI meter and it is peaking around 9.8 amps when the controller is using the PWM heating mode.

Comments