For the past four years, we have been using a CIF CF02 reflow oven to reflow and cook our circuit boards which we sell on www.abelectronics.co.uk and for our own projects.

The oven initially needed a lot of tweaking to get a reliable reflow process with the boards but overall it has been working ok until the last few weeks when we started to get inconsistent results with cool areas on some boards.

We removed the cover from the oven area and found that the thermocouple was badly corroded with flux residue. I cleaned the flux from the thermocouple but after reassembling the oven we found that it was not working correctly and after two more test cooks there was a bang and smell of burning plastic coming from the controller box on the side of the oven.

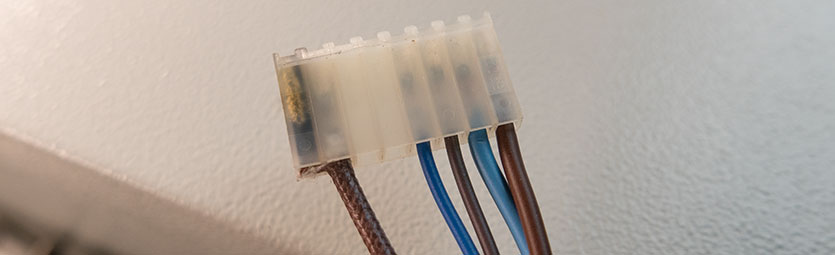

Removing the cover on the controller box showed that the mains cable which goes to the heating elements was damaged where it connected to the solid-state relay on the controller board as shown in the photos below.

The burnt and damaged mains power connector on the CIF FT02 control board.

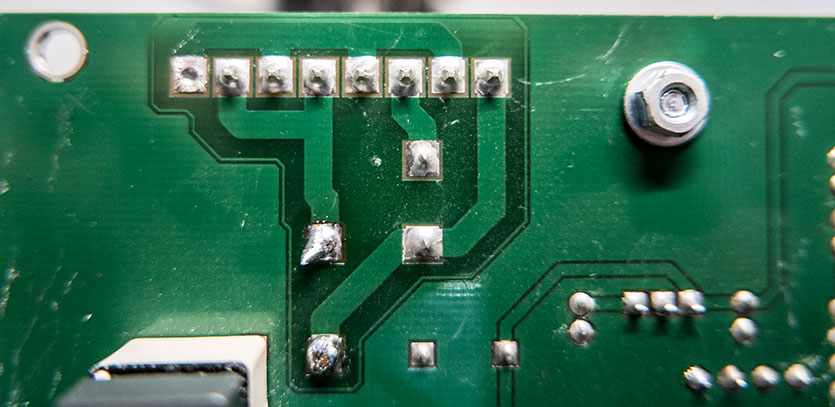

We removed the controller board and found that the solid-state relay was also damaged and the mounting pins/stands had come loose.

When inspecting the board we thought that the space between the mains voltage pins and the ground plane on the board seemed very small and a quick google search found a long thread on the EEV Blog forum about this reflow oven and the dangerous problems with lack of mains isolation on the board.

The base of the damaged mains power connections on the CIF FT02 control board. The clearance between the mains 240v AC lines and the GND power plane is very small.

With the control board removed we inspected the power supply board on the side of the case and found areas which appeared to have overheated causing burn marks around some of the power resistors as you can see in the photos.

CIF FT02 reflow ovens power supply shows signs of overheating on the base of the board.

The top of the power supply board shows heat damage around the resistors.

I contacted the supplier of the reflow oven and I was quoted over £85 just for a new thermocouple (less than £10 from Farnell, RS etc for a similar model) and with the power and control board also needing to be replaced we took the decision to replace the control board and associated power control with a new system which is higher rated for the mains current requirement with suitable heatsinks and cooling.

The new Zallus Designs - Zallus Learning Controller Deluxe Kit

We found a temperature controller system on Kickstarter called Zallus Reflow Oven Controller which was an all-in-one solution with a touch screen and control board which appeared to do everything we needed.

The designer and manufacturer of the board is Nathan Zimmerman who has a website called Zallus Designs at http://www.zallus.com/ and sells an updated version of the Kickstarter board called Zallus Learning Controller (http://www.zallus.com/shop/) which is available in two versions, one with a learning controller board with case and a deluxe kit which has a solid state relay, heatsink and mains cables/ sockets included.

The controller board uses a built-in Wi-Fi module to create a Wi-Fi network to which an Android tablet/phone connects and Nathan has written an Android and a desktop app to control the system.

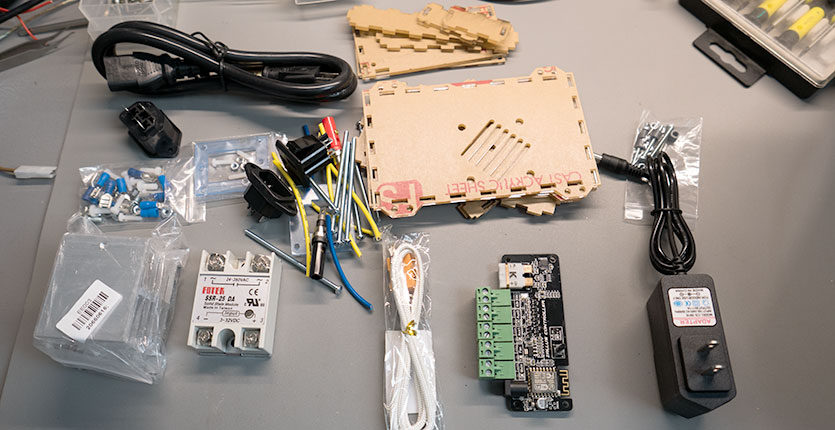

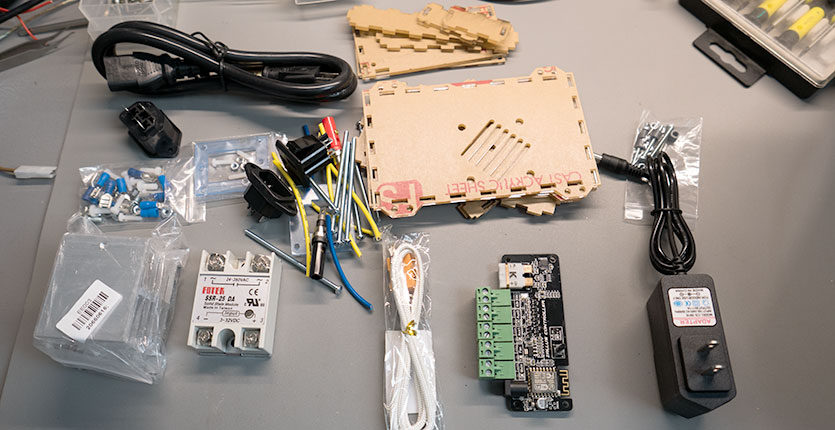

I ordered the deluxe kit and it arrived just over a week later. The photo below shows the contents of the kit with the plastic laser cut case, all the screws, nuts, bolts, wires, connectors, mains power supply, thermocouple, solid state relay, heat sink and all the other parts needed to use the kit.

Zallus Designs - Zallus Learning Controller Deluxe Kit contents.

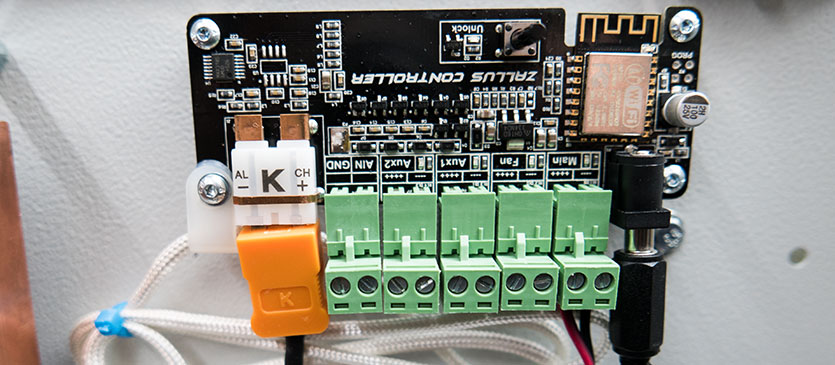

The control board is very compact and measures 99mm x 37 mm (excluding connectors) and has all the power, screw terminals and sensor inputs along one edge. There are mounting holes in each corner making it easy to fit into the existing case using M3 bolts and spacers.

The supplied thermocouple had a long lead and so we had to fold this under the board once it was fitted as the oven only needed a short length of cable to go to the middle of the PCB tray and had to sit approx. 1cm above the PCB boards when being reflowed.

Zallus Designs - Zallus Learning Controller board with power, thermocouple and one solid state relay connected.

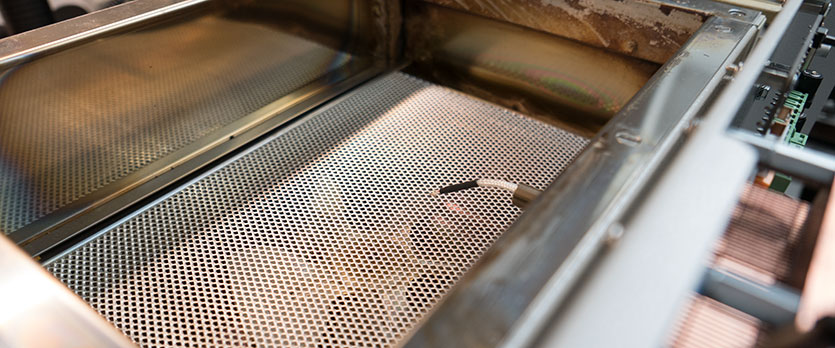

Thermocouple fitted into the cooking area on the reflow oven.

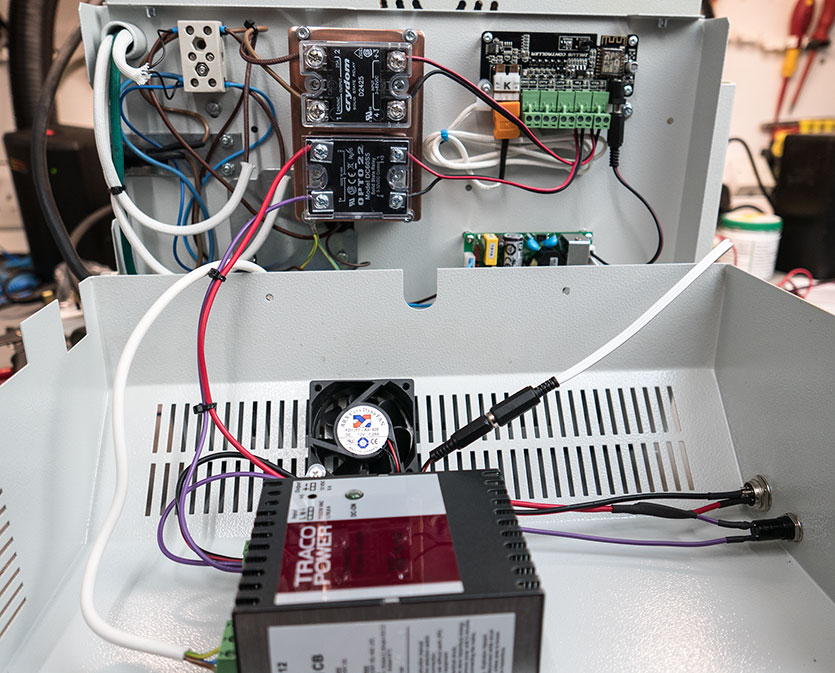

We needed to use two solid state relays and so we used a 25 amp AC mains rated solid state relay for the heating element control and a 5 amp DC solid state relay to control the external cooling fan which is mounted to the front of the unit when being used.

To power the control board and the cooling fan we purchased an open-frame 9V power supply and for the fan we used a 12V power supply module from a previous project.

The reflow oven has a hot air circulation fan built into the base which is controlled by a roller-type microswitch activated when the PCB drawer is closed. This is supposed to ensure an even temperature when reflowing the boards but our own tests and other peoples’ tests have shown that the temperature can vary by several degrees across the drawer area.

The solid-state relays for heating elements and cooling fan are installed with a 9v and 12V power supply fitted to the case.

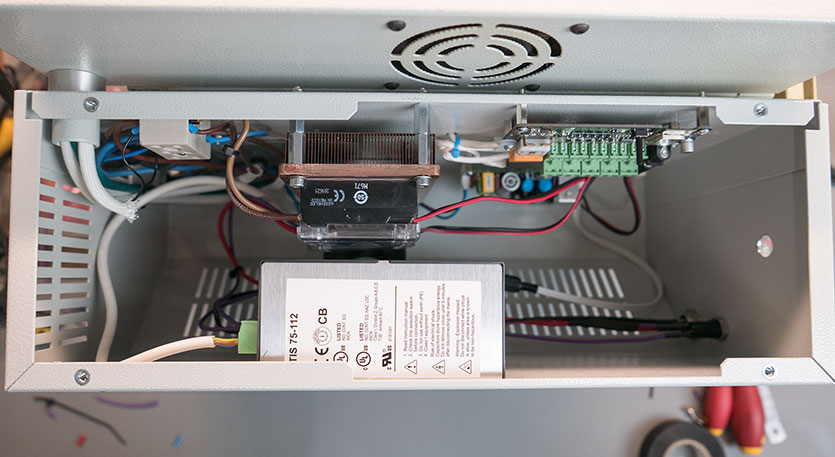

With the control board case side reassembled you can see there is a small space between the solid-state relays and the 12V power supply unit. To avoid any electrical issues, we fitted plastic covers on the relays.

The spare hole in the front of the case will be later used by a push button switch to activate the “enable” button on the new controller board which must be pressed each time the controller is connected to the Android app. I emailed the developer about this to see if there was any way to avoid having the extra button but Nathan told me that it is an additional security step to avoid anyone else using the app to remote control the device being used.

Top view of the installed components.

The new control board has additional outputs for fans and so we decided to use the forced air cooling fan we had previously made and which we had used with the door slightly open to cool the oven. We modified the drawer front to allow a small airflow into and out of the cooking area when the heating stage has been completed.

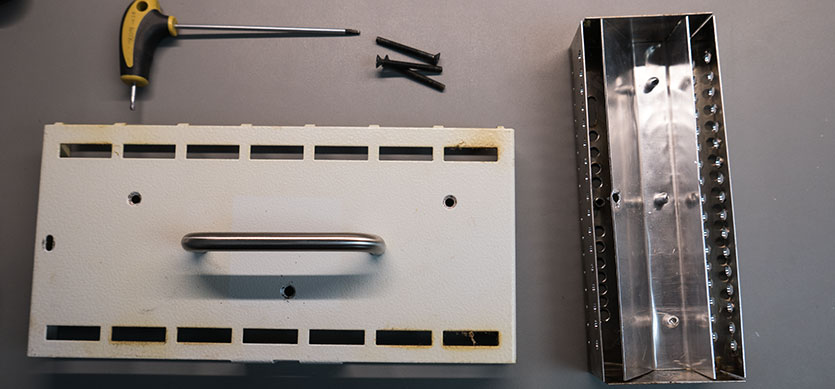

The drawer front is made from folded stainless steel and we drilled a series of 5mm holes along the top and bottom of the drawer back (inside the reflow area) and a row of 5mm holes on the top and base of the folded box to allow air into the drawer via the fan and to exit the top to be removed from the room by the extraction system.

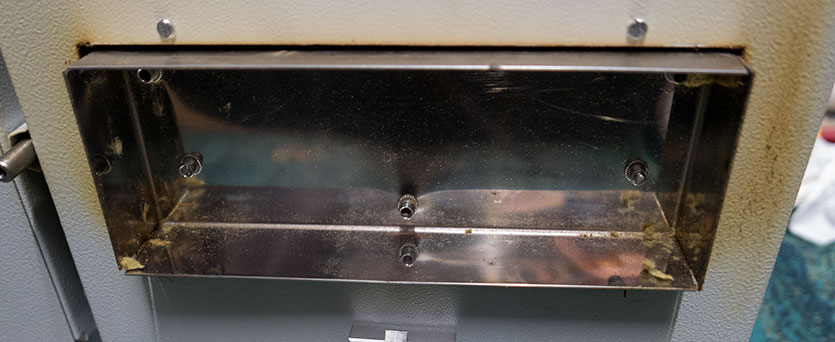

The reflow oven door before modifications.

To stop the air from going direct in and out of the drawer front, we made a folded baffle from some 1mm alloy sheet which was riveted in place. The front of the drawer with the opening handle was then reattached and the oven's draw was fitted back into place.

The reflow oven door after modifications to allow cooling air to be directed into the bottom which then goes into the cooking area and exits via the top of the door.

The old control box was made from sheet steel and as the new control board uses Wi-Fi we needed to use a non-metallic top cover. I called our local sign maker who cut a sheet of clear acrylic to fit the case. This also allows us to see the status LED’s on the Zallus controller board when it is in use.

The oven back in the box with the cooling fan and fitted. The new buttons on the controller are for a fan override and the enable button for the new controller.

The Android Software

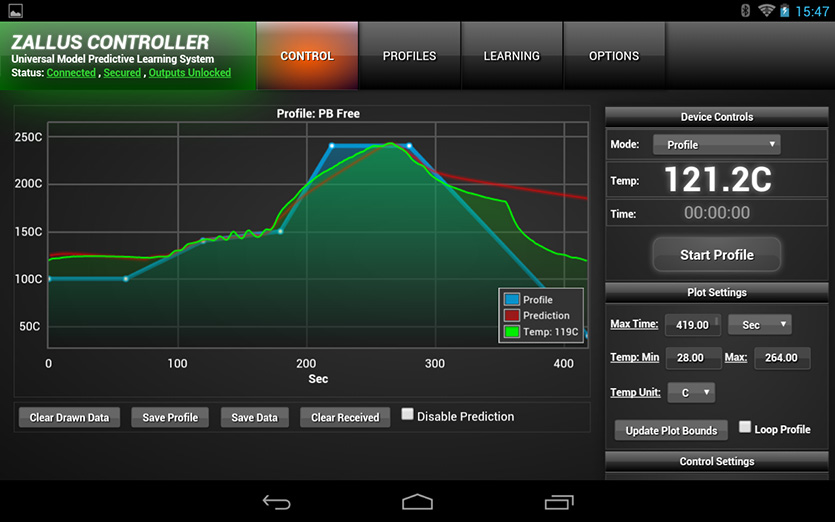

The Zallus Controller Android app was installed on an old Nexus 7 tablet and this connects to the controller board via Wi-Fi, on the first connection you are prompted to set a password for the wireless network and then the board was rebooted which enabled the new password-protected Wi-Fi network.

Once the app is connected I needed to press the unlock button on the control board (via external front panel switch) which allows the app to use the heating and fan outputs.

The first stage is for the board and app to learn the heating and cooling profiles of the reflow oven and it does this with a series of heating and cooling steps over a 30-minute period. The test is run several times to get the best results.

The learning profile allows you to set the mode for the heating and cooling to switch using PWM or on/off modes with minimum times for the on/off mode being set in the software. We used PWM on the heating mode and on/off with a 1-second minimum for the cooling fan to allow the fan time to spin up to full speed.

Android app running the learning profile to calibrate the oven and cooling.

After running the learning profiles, we saved the config settings into a new device profile and then created new reflow profiles based on the ones supplied with the oven for the PB Free (lead-free) solder paste we use.

Android App running the cooking profile to reflow our Raspberry Pi development boards.

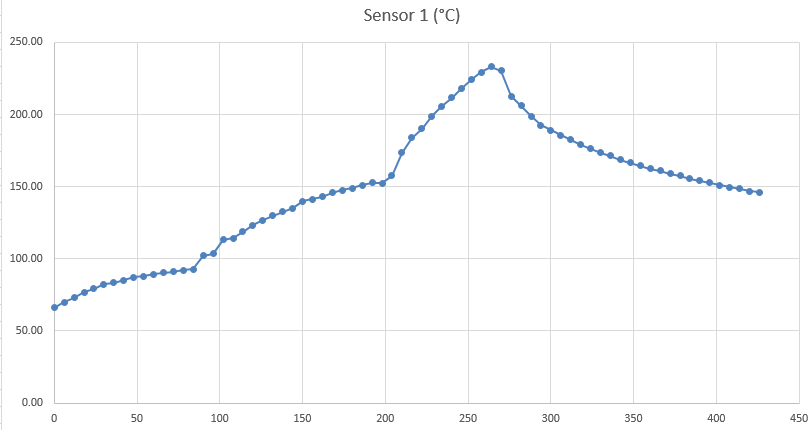

We used a “Thermocouple ThermaData loggers for high temperature applications” which we purchased from http://thermometer.co.uk/ to then record several reflow runs and saved the data to a spreadsheet with the result shown below. The scale is shown in Degrees C and in Seconds.

Output from the temperature data logger on a profile run.

We then made a small batch of RTC Pi boards and on the first reflow batch we found that the maximum temperature was not held for long enough to give a full reflow across all the boards and so we increased this by 20 seconds which give us very good results on the remaining board batches.

Now the reflow oven is working again, we can catch up on our board production and also work on the model railway project which is slowly coming together.

I would like to thank Nathan at Zallus Designs http://www.zallus.com/ for his excellent help and tech support over the last couple of days with the config and usage if his controller kit and app.

Related Links

Zallus Designs - http://www.zallus.com/

Zallus Designs Resources page with datasheets, API and software - http://www.zallus.com/resources/

EEV Blog post about original controller issues - http://www.eevblog.com/forum/reviews/deadly-insane-design-(cif-ft-02-reflow-oven)-teardown-rant-safety-fix/

Temperature Data logger - http://thermometer.co.uk/

Adrián

Hi, my name is Adrian and I'm interested in buying a Zallus Reflow Oven Controller kit and would like to know if it's available for sale

Brian

I ordered mine from the zallus website, link is above, but the shop page is showing it as being out of stock. You could try contacting the manufacturer to see if they have any left or a circuit schematic and code you can use to build your own

Milan Misun

Hi, my name is Milan and I'm interested in buying a Zallus Reflow Oven Controller kit and would like to know if it's available for sale. Please help me. I know it's not selling anymore, but this project really impressed me and I would like to have it at the cost of building it myself, I just need a schematic and a pcb image. Thanks.