The basic Chinese Vacuum Pickup pump we have been using on the DIY pick and place machine has been giving us problems with its lack of suction when handling larger SOIC components and didn’t hold them still when moving fast or rotating the parts.

I found a used Charles Austen Capex L2 vacuum pump/compressor on eBay and found that while the suction was much better it suffered with a pulsed output and was also very noisy in its metal case.

I found a used Charles Austen Capex L2 vacuum pump/compressor on eBay and found that while the suction was much better it suffered with a pulsed output and was also very noisy in its metal case.

To solve these problems we removed the pump from its box and suspended it under the bench on a silicone hose originally designed for air supply for a fish tank which greatly reduced the vibration and noise from the pump motor.

Next, we had to solve the issue of the noise from the pump outlet which was noisy with the airflow. I had a spare PC water cooling radiator which had the same size plumbing fittings as the pump outlet. Filling the inside of the radiator with loose cotton wool completely removed the noise from the air outlet.

To give a larger buffer and smoother airflow on the vacuum we mounted a 3L 300bar diving bottle under the desk and using a T piece fitting connected the pump to the bottle and the control valves on the pick and place machine.

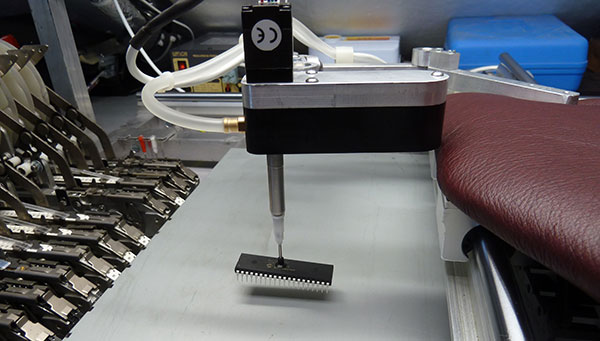

The photo below shows the new suction abilities when lifting a large DIP chip.

Comments