While soldering boards today one of our Metcal SP200 solder stations stopped working with a quiet pop and some magic smoke* came from the case.

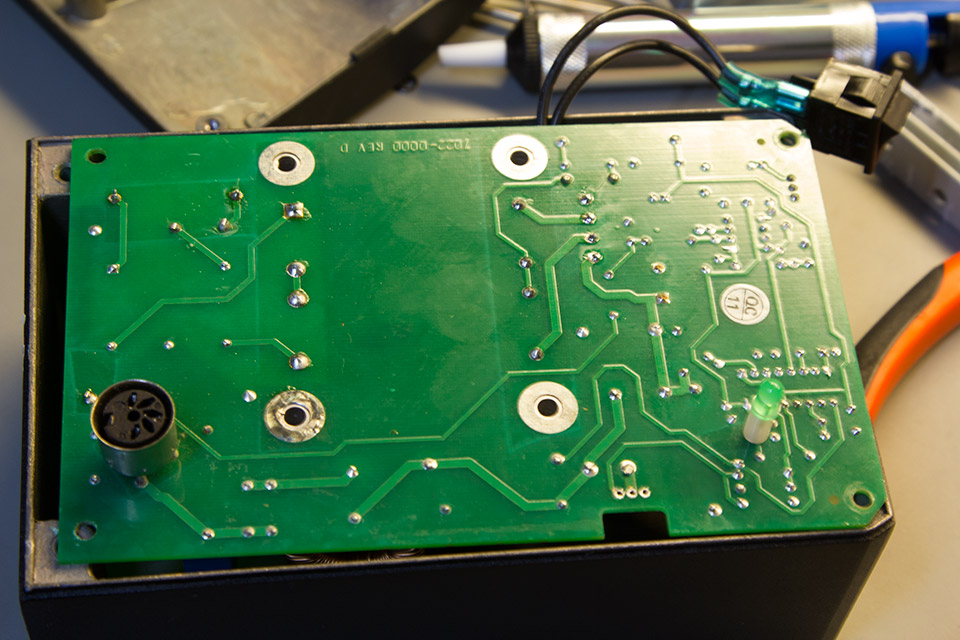

We removed the case of the power unit and found that the internal fuse had blown. The fuse was soldered to the PCB so we removed the fuse and found a spare fuse holder for 20mm fuses which fitted into the old fuse holder holes. After fitting the new fuse holder we tried to power on the unit and after a flash of light from the new fuse, it blew again.

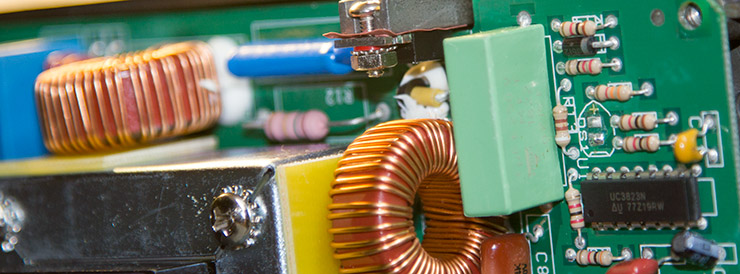

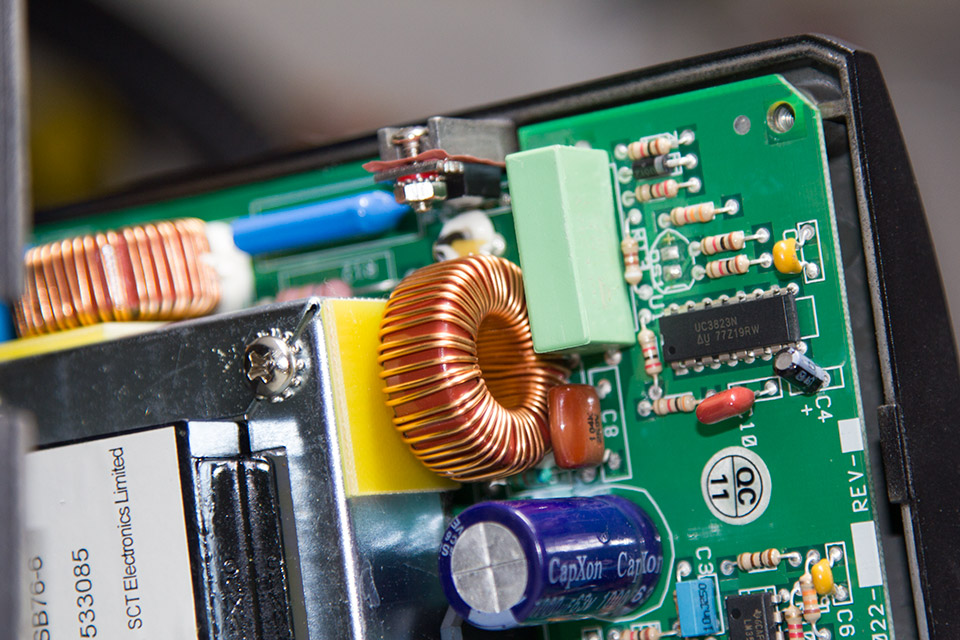

We have a couple of spare SP200 power units so we removed the covers from a working unit and proceeded to test the broken one to check the resistances of the components compared to the working unit.

The bridge rectifier was removed from the dead unit so we could test the resistance of the transformer coils to check for short circuits but this was found to be ok, on the positive and negative outputs of the rectifier, we found that there was a very low resistance short of approx. 0.2 ohms.

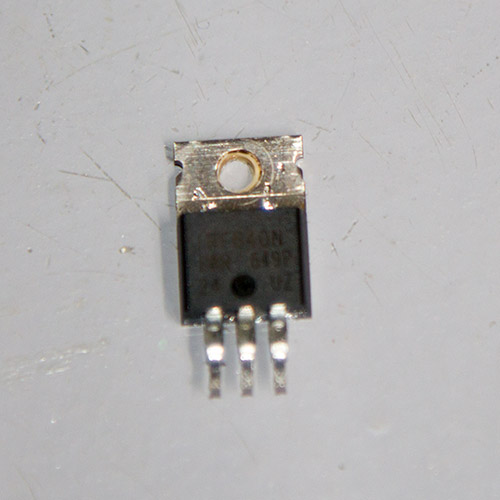

After tracking the route of the power output across the board and by checking each component to measure the resistances, we found that the power MOSFET (IRF840N N-Channel Mosfet Transistor) which appears to switch between the output to the iron and the power supply had the lowest resistance and after unsoldering it we found that all three pins on the MOSFET were short-circuited.

The PCB was rechecked again with the MOSFET removed and the short circuit problem had vanished so it appeared that we had tracked down the source of the problem and smoke.

After a hunt through our MOSFETs tray, we found a similar specification N-Channel Mosfet and this was fitted back onto the PCB and the unit was powered up.

The front led lit and after a few seconds, I checked the temperature of the soldering iron tip with a damp finger and burnt myself so it appeared to be working ok!

We let the unit run for 20 minutes before reassembling the case and now the Metcal SP200 soldering station power supply is ready to use again.

* magic smoke = http://en.wikipedia.org/wiki/Magic_smoke

Steve

One of mine stopped working yesterday. No blown fuse, the green LED comes on, but the iron will not heat up. I swapped the iron with a working unit and the problem stays with the base. I've measured quite a few components and so far can't see anything obviously bad. Does anyone have a schematic or service manual for these? Or a calibration procedure for adjusting that 1K pot on the board?

Mark

A very good job T/S without tech data Brian. Congratulations.

Steve- we have four bad ones at our company also. Exact same symptoms as yours, green light no heat produced. Did you have any luck figuring out yours? I guess I'll be digging into these soon to see if we can save them.

Thanks in advance, Mark

frederic

Steve and Mark,

I have also the same symptoms on my PS900.

The schematic of SP200 can be found using "metcal_sp200_sch.pdf"

I believe the 1k potentiometer sets the switching frequency.

I have seen that for PS900, the frequency should de either 450 or 470kHz

On my unit (very little heat generated) the frequency is about 350kHz

frederic

Quick update:

My PS900 soldering station is now working.

The 1k potentiometer was bad.

Just touching the potentiometer was enough to change the frequenc to the correct value.

I replaced the potentiometer to prevent the same problem in the future.

Fikri

Can i convert or modifiying with T12 handle and Tip? Cause in my country no one selling the cartridge. For about 10 years my sp200 can't be operated cause I have no cartridge. Please mail me if anybody can convert it. Thank U

Essam

Fikri,

These are two different systems!

The SP-200 cartridge is heated by HF-induction, the T12 cardtrifgd is resistive heating; so the answer is no way!

Greetings

Eric

At which point to measure the switching frequency 450kHz SP200. thanks.

Brian

Hi, I am sorry but I dont know the measuring point on the pcb