While assembling printed circuit boards (PCBs) using our manual pick and place machine, we explored a range of options to securely hold the PCBs in position during the component placement process. The goal was to find a simple and effective solution that didn't involve using complicated clamps or fixtures, which can be time-consuming to set up and adjust.

To address this issue, we experimented with using small neodymium magnets to hold the boards in place. After some testing, we discovered that combining the magnets with a 1mm thick steel backplate provided a reliable and convenient method. The magnets were strong enough to keep the PCB firmly in place during assembly, yet allowed the board to be easily removed once the work was complete.

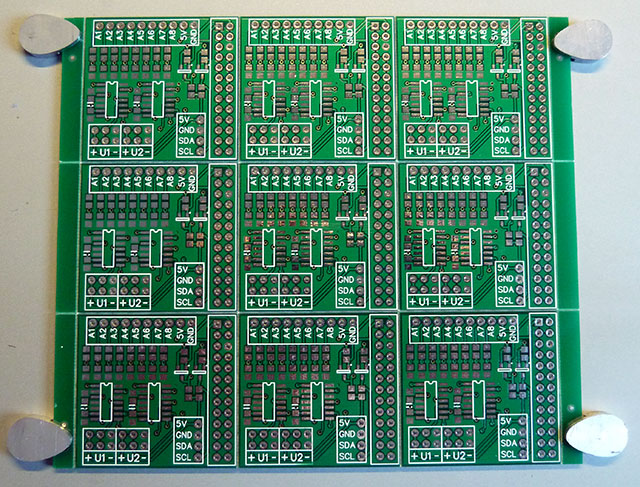

To make the system more practical, we machined a set of small aluminium clips, each fitted with a neodymium magnet measuring 8mm in diameter and 1mm thick. The magnets were securely glued into the base of each clip. We also added a shallow 1.4mm recess to the edge of each clip, allowing it to gently grip the edge of the PCB and hold it securely without damaging the board.

This simple magnetic system has proven to be a very effective way to keep PCBs stable during manual assembly, without the need for complex mechanical clamping solutions.

Comments