The new DIY pick and place machine needed a way to feed SOIC, TSOP and other tube-supplied chips to be picked and placed using the machine.

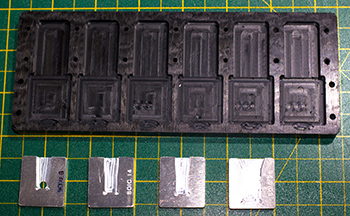

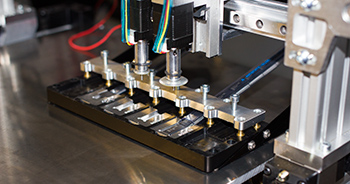

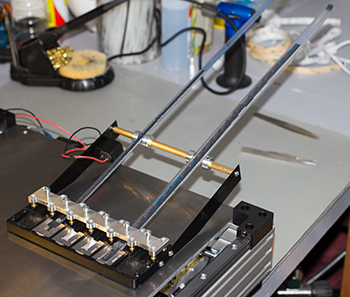

After looking at a lot of commercial and DIY solutions we decided to build a fixed base with removable chip inserts to hold up to six tubes/chips and be easy to change component tubes with a simple clamping system.

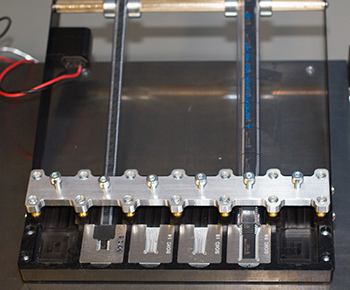

The base of the vibratory feeder was milled from a section of 11mm thick Delrin and the chip holders were milled from a sheet of 4mm aluminium plate which fit into the base.

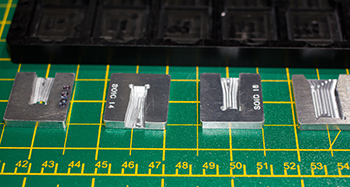

Each of the aluminium plates is machined so the chips will always have their centre point at the same Y location on the main axis. We have machined four plates so far for SOIC 8, 14, 16 and 28 chips, we intend to make more for other chip sizes including TSOP packages.

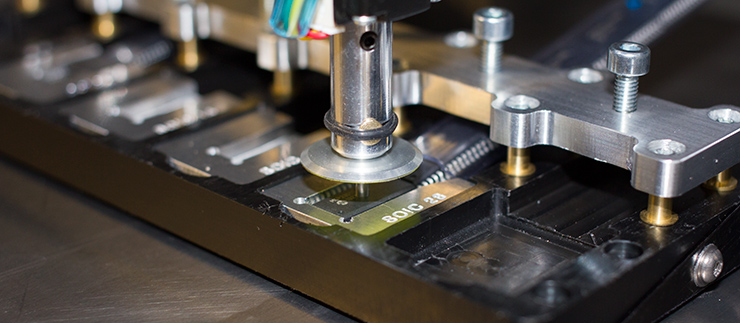

The feeder system was made to fit under the main picker gantry arm and have clearance for the largest picker nozzles we have which are 20mm in diameter.

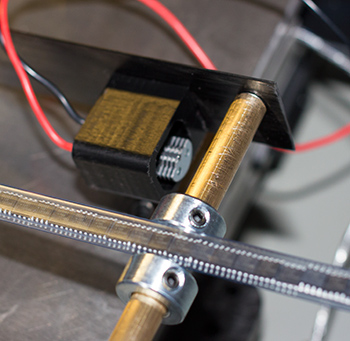

The sides of the feeder support the tubes of components are made from 0.5mm thick carbon fibre and this has the vibration motor fitted to one side. The back support is an 8mm brass rod and will have additional spaces to support all six component tubes.

The lower block has a 6mm thick plate with bolts which hold each tube in position.

The vibration motor was sourced from a Microsoft Xbox game controller and runs at 3 volts. We will be making a simple PWM control circuit with a timer which can be triggered from the PC and Smooth Stepper board to feed the chips as required.

The video below shows a short test using SOIC 8 and SOIC 28 chips in the feeder tubes.

Alan

Very nice!