After using our previous semi-automatic pick and place machine for a year we decided it was time to build a fully automatic DIY pick and place machine as we can't keep up with the demand for the Raspberry Pi development boards. We have looked into buying a commercial ready-made system but they are very large and very expensive.

We are going to be using the same modified Panasonic Ratchet Type Component Feeders as used on our semi-auto machine and this will allow us to use the same components on the old and new pick and place machines.

After a lot of research into other DIY pick and place machines which have been built, we decided to go with a belt drive system and dual picker heads. The reason for choosing the belt drive over a ballscrew was for speed and also the much larger cost involved with using ballscrews and all the associated mounts and bearings. The pick and place machine is being designed so it can be changed to use ballscrews later if needed.

To drive the pick and place machine we are going to use stepper motors and these will either be controlled via Mach3 or LinuxCNC with OpenPNP) and a camera system will be fitted to allow OpenPNP to correct the rotation of any components which are not central on the picker needles.

The frame of the machine will be built from Series 5 aluminium profile which we have purchased from Metallin, this will make it much easier to build and modify the frame as we add the various motors, bearings, drive systems and sensors.

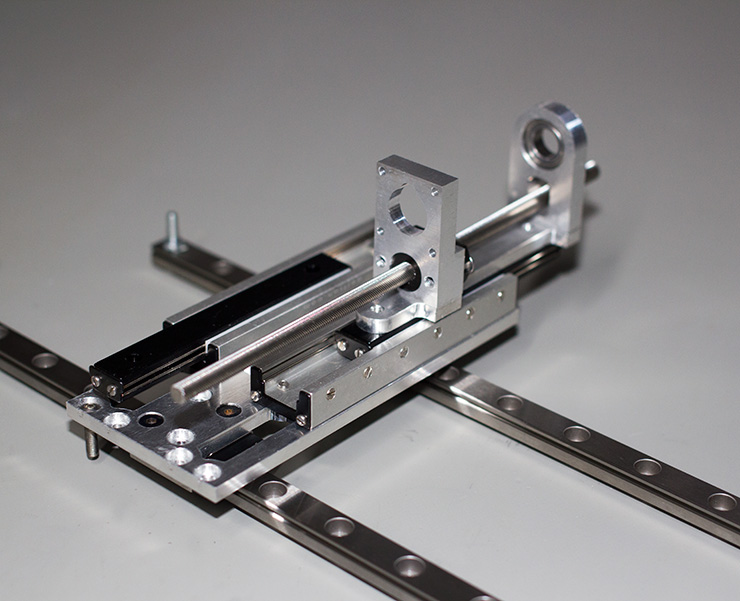

The X-axis bearings are part no LBC 15 WS Z1 from Hepcomotion and the Y-axis bearings are IKO Linear way LWL R390 (390mm length) sourced from eBay. The 2 Z-axis bearings are Del-Tron Slipless Linear Bearing EA-3 also sourced from eBay.

The picker head will be using a pair of NEMA 8 stepper motors to drive the Z-axis and a pair of hollow shaft NEMA 8 stepper motors from Robotdigg to turn the picker needle with the vacuum being supplied via control valves to the picker head.

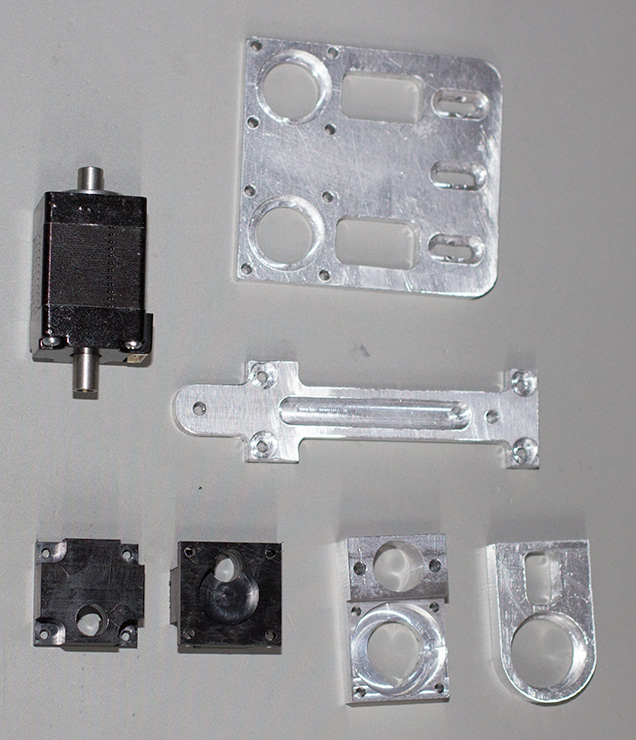

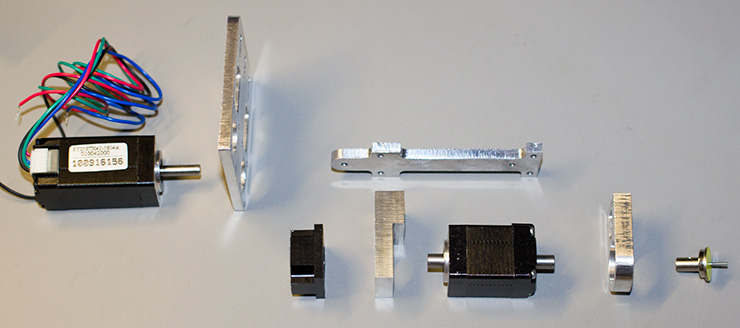

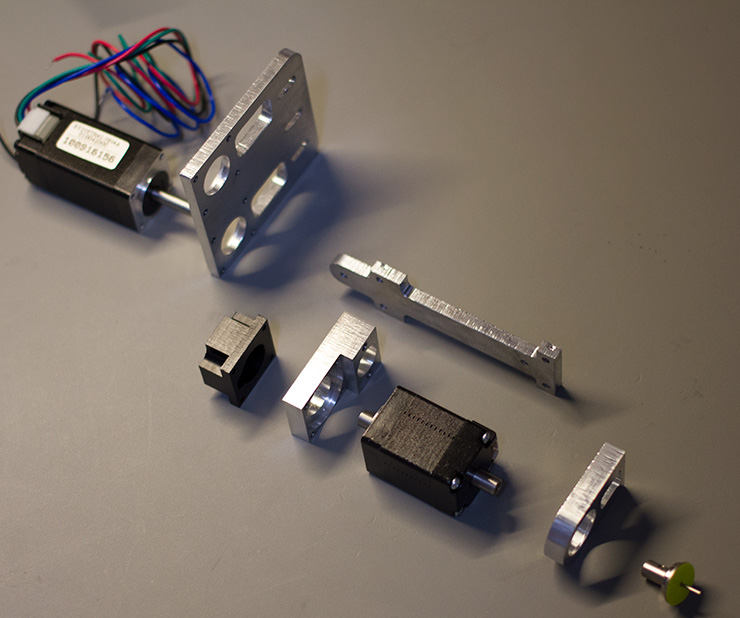

The photos below show the various components which we machined on our CNC mill to make up the Z-axis head assembly.

Head components, starting left: NEMA 8 hollow shaft stepper, Z-axis motor mounting plate, Z-axis bearing plate, stepper motor top cover with vac hose hole, stepper motor mount and base support bearing bracket.

The picker needle and pickup nozzles will be made from 10mm steel and use hollow magnets to attach the picker needles. This will be covered in a future blog post.

Comments