After discovering the cost of buying a ready-made manual Pick & Place Machine was over £5,000 and an automatic one well over £20,000 we decided to try to make our own manual pick and place system with a motorised component pen.

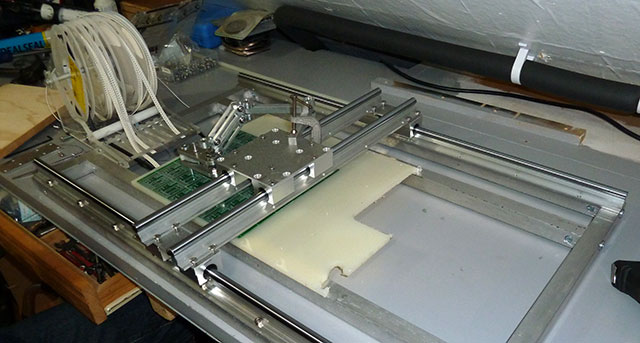

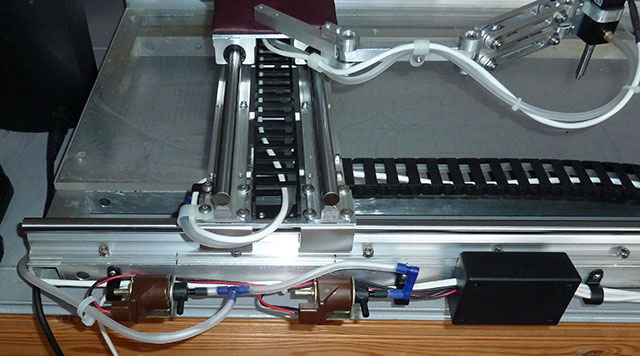

We sourced some linear rails from eBay and other bearings from a local model shop and built a frame which is 80cm x 50cm.

The longer linear rails were trimmed to fit and bolted to the new base which is made from square tube aluminium.

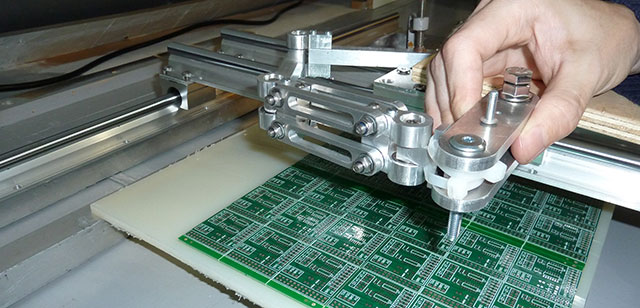

An arm was machined from 10mm and 6mm aluminium sheets and uses RC car bearings for all the pivots. One end is fixed to the hand rest and the other will have a pen holder and motor assembly with a vacuum valve fitted.

The arm was test fitted with a small clamp to the temporary armrest to check the range of motion available. The end plates were fitted using cable ties to find the best position.

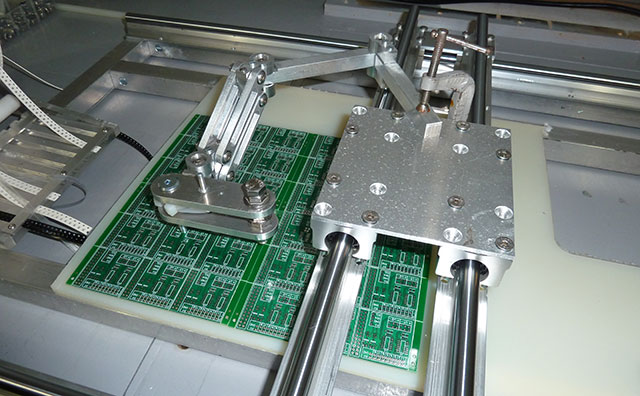

Top view of the armrest and pen arm. The surface mount component dispenser tray is on the left of the photo.

The machine so far, next job is to make a better armrest and fit the pen arm in place. Then start work on the vacuum pen and associated controls.

The total cost so far is around £200 with most of that being the cost of the linear rails and bearing blocks.

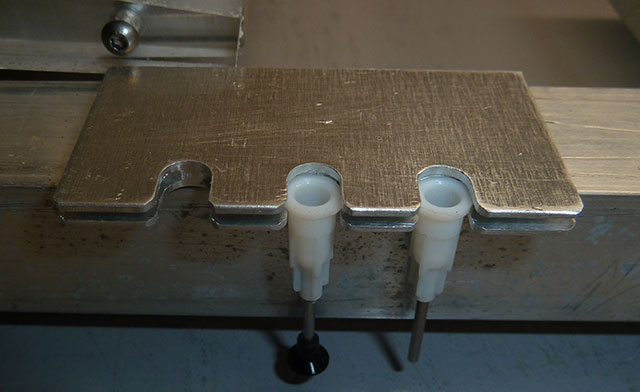

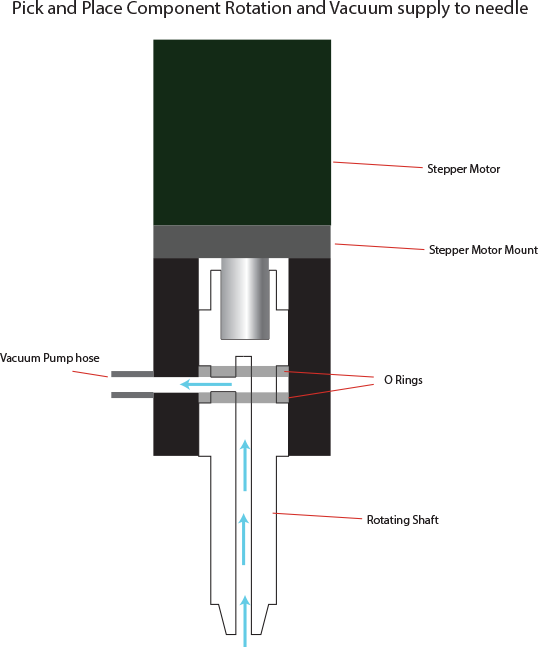

The air/vacuum supply nozzle was made on the lathe using a section of 10mm steel and has a 4mm hole approx 3/4 the length in the middle and a smaller 2mm hole at the end where the needles fit. The vacuum is supplied via a side hole in the shaft and uses O rings to seal against the body.

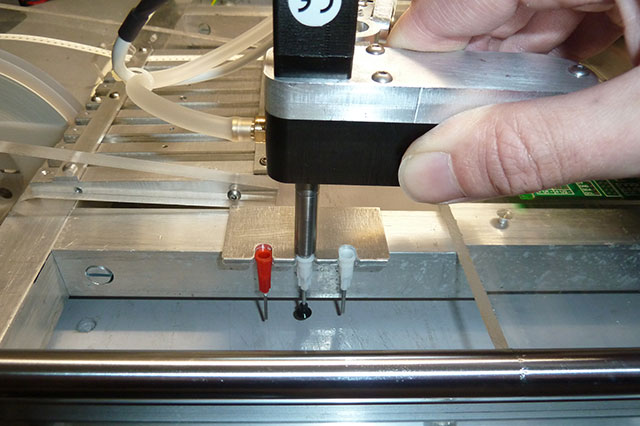

The top place was machined from 10mm sheet aluminium and the stepper motor was fitted using M2 bolts

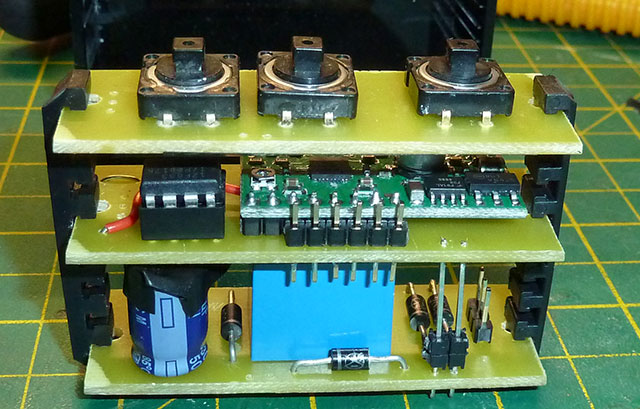

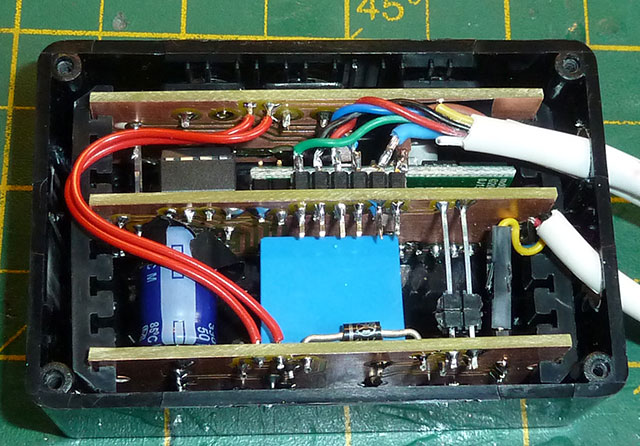

The stepper control circuit, valve control relay and selection switches are driven by a PIC processor and a Pololu A4988 Stepper Motor Driver Carrier + Voltage Reg from www.technobotsonline.com

The two switches on the left turn the stepper motor by 90 degrees either left or right and the third button releases the component by switching the valves to shut off the vacuum and allow air in via the second valve.

The control boards are fitted in the box and the cables are fitted.

The cables and vacuum pipe were run along the length of E-Chain ® from www.igus.co.uk which cost only £59 including postage.

A pair of 12V vacuum valves were sourced from eBay for £6 each and these switch between the vacuum pump and optional compressed air or open air to release the component.

The basic Chinese vacuum pen kit I got from eBay for £22 was supplied with a single needle size and had an optional rubber end for picking larger components. We machined a small needle holder from a section of 4mm flat aluminium with a 1.6mm channel and then milled slots for the needles.

The needles are easily changed when in use by gently pushing down on the needle required and then sliding out of the holder.

The completed machine is ready to use once our new reflow oven arrives.

The total cost so far to build is approx £444

| Item | Cost |

| All Aluminium materials | £100 |

| Air control Valves | £12 |

| Vacuum Pump | £22 |

| Rails and Bearings | £150 |

| Other bearing races | £15 |

| Stepper motor and controller parts | £40 |

| Cable e-chain | £59 |

| Plastic boxes | £8 |

| Misc nuts and bolts | £20 |

| Perspex for base | £10 |

| Air hose and fittings | £8 |

| Total | £444 |

At the moment we are going to be using the manual component feeder mounted on the left of the machine but are looking into different options to make automatic feeders.

The image below shows how the pick and place needle assembly is connected to the vacuum pump and can rotate without loss of suction:

Roberto grassi

should be possible to buy this kit. It's interesting to make my own prototype..