Since launching our AB Electronics UK shop in 2012 we have expanded from our first Raspberry Pi analogue to digital converter to over 40 custom boards and accessories we sell online at www.abelectronics.co.uk/.

This blog post shows how we develop, design and launch a new product to sell online or improve and revise an existing product.

Many of our development boards have been developed after emails and feedback from customers who have asked for additional functionality or a completely new board to meet a specific task such as the RTC Pi which is a real-time clock module for the Raspberry Pi to keep the time when the Raspberry Pi is powered off.

The Raspberry Pi has a GPIO bus which has 3.3 volt rated inputs and outputs and due to this voltage level, we received a lot of requests for a 5 volt tolerant I/O board. After developing several prototypes we launched the IO Pi which is now sold as the IO Pi Plus with 32 IO channels and the IO Pi Zero with 16 IO channels.

All the products we have developed and sold over the past seven years have been entirely funded from our own savings and business turnover as we have never borrowed money from the banks to expand the business.

Below are the different stages to bring a new product to market based on a current product we have in development now.

1. The Idea

The idea for a new product to fulfil a need or requirement can either come from our own projects with the Raspberry Pi or based on customer feedback or suggestions via email, support forums or social sites such as Reddit and Twitter.

Current project:

The product we are currently working on is an I2C bus switch to allow additional I2C buses to be added to the Raspberry Pi. The Raspberry Pi only has a single I2C bus available and so if you have I2C devices which share the same I2C address, you would only be able to use one on the Raspberry Pi. With the new I2C switch it would add an additional four I2C ports onto the GPIO header.

2. Research

The research stage involves finding suitable ways to fulfil the needs and specifications of the project such as finding integrated circuits and required components.

We also look at competing products to see if there is a potential gap in the market or to be able to bring a new product out to fill an existing niche.

For the I2C Switch, we found a suitable IC from Texas Instruments which is a PCA9546A. The PCA9546A is available as a SOIC package and uses very few additional components.

3. Prototype

The prototype stage is where we design a circuit schematic and PCB (Printed Circuit Board) using Diptrace and order a small quantity of prototype PCBs for testing.

Once the initial prototype PCBs arrive, they are assembled and tested to ensure they work correctly with custom code libraries being written for the new product. At the moment we provide code libraries for our boards in C, C++, Node JS, Python and . NET.

Any design or layout issues with the PCB are corrected and new PCBs are ordered, and the process is repeated until we are satisfied that the circuit and software are ready to proceed to the sourcing and manufacturing stage. This can take several months due to delivery times for the prototype PCB suppliers.

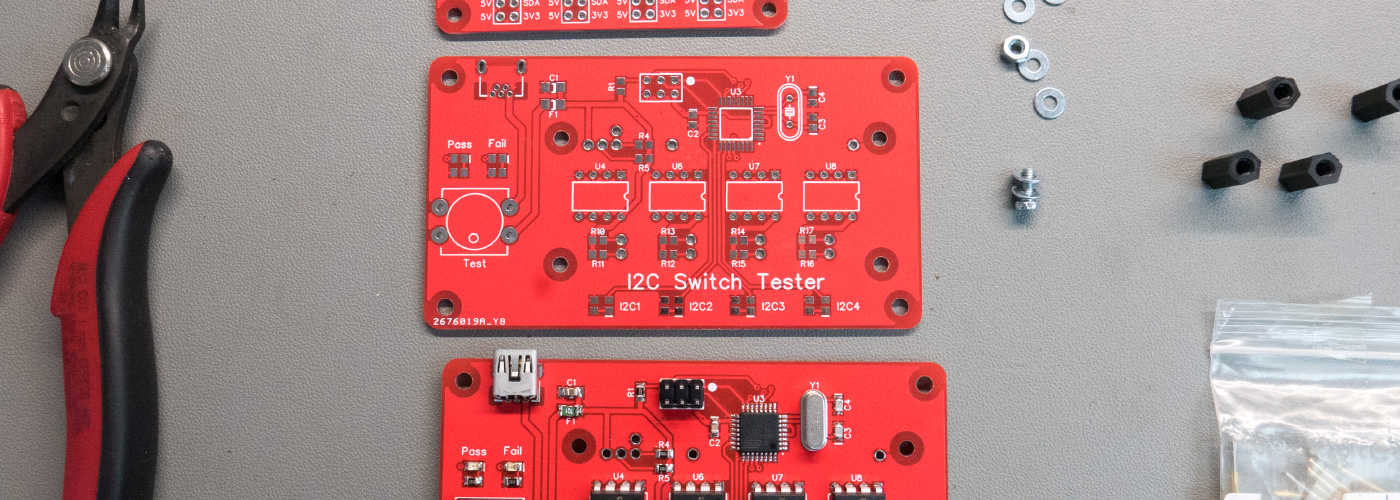

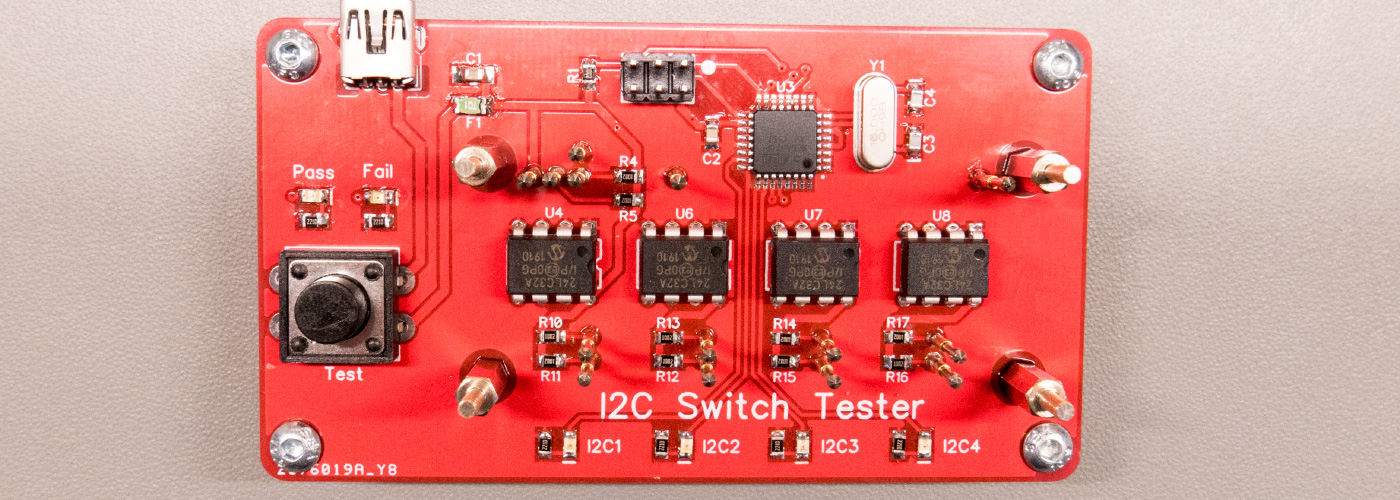

Making a test jig

A test jig for the new product is also developed at this stage so we can easily and quickly test the new development board.

The test boards we design use either an Atmel ATMEGA or Microchip PIC processor and the firmware is written and flashed to the tester using a debug header. Depending on the type of testing required the tester can have simple indicator LEDs to show a pass or fail state or have an LCD display to show the test status for multiple pins or test modes.

4. Sourcing

We find suppliers for each of the parts required with backup suppliers in case of component supply issues.

We also source packaging materials and we use anti-static bags to package our products with labels and barcodes being printed using a Dymo Label Printer.

If we sold our products to be sold in a retail shop, we would design printed packing boxes and associated retail packaging for each item. This would greatly increase the cost of the item and so we decided for mail order it was not worth adding the cost onto the product for packing which is only going to be disposed of once it is opened.

For ICs and passive components, we normally order from the following suppliers here in the UK.

https://www.futureelectronics.com/

https://www.microchipdirect.com/

5. Costing

After finding suppliers for all the components and parts needed, we would create a spreadsheet containing the costs of each part so we can determine a build price and retail price taking into account the time it will take to build each product and the BOM (Bill of Materials) cost.

6. Ordering the parts

Next, we would order the final design PCBs from our usual supplier who is based in the United Kingdom and order any ICs and other components needed for the product from the supplier's list.

We would also order a paste stencil for the new board for assembly.

We normally work on a minimum quantity of 1000 PCBs and order enough chips and other parts to build the initial 1000 boards.

This can cost from a few thousand pounds to over ten thousand pounds depending on the parts used and order quantities.

The PCBs normally arrive within six to eight weeks and then we move onto the manufacturing stage.

7. Manufacturing

We manufacture the finished product in-house using our DIY pick-and-place robot and the boards are then reflowed in our reflow oven.

Once the boards have been pasted, placed and reflowed they are then tested individually before being packaged into anti-static bags with any associated connectors and a product sticker added to the outside of the bag.

8. Marketing

Once the new product is completed, we would take high-resolution photographs of the item and write the text for the product page on the website shop www.abelectronics.co.uk/

Software libraries would be added to our GitHub repository at github.com/abelectronicsuk with demo code showing how to use the new product.

Social Media

We use Twitter for most of our online marketing as we have found this has the most shares for each of our product launches and company news.

In the past, we did have a Facebook page, but we found that the response to new posts was very poor and Facebook would continually try to get us to spend money on each post to show it to a few hundred people each time.

We also share videos on our business YouTube channel and also on my personal YouTube Channel which helps to raise awareness of new projects and things we are working on.

Comments